“The winged profile of Chennai Airport”

“The winged profile of Chennai Airport”

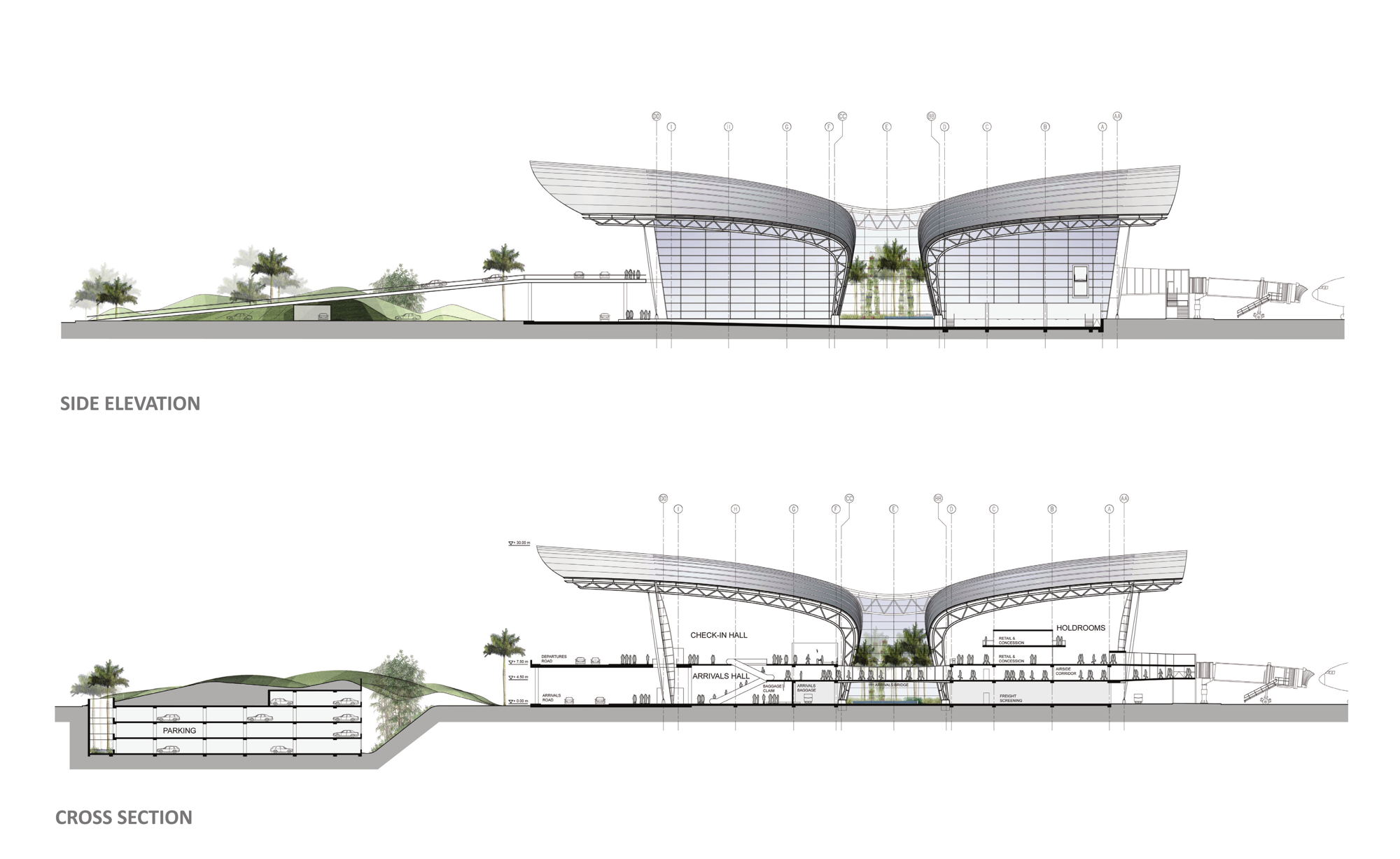

The wings of a bird in flight inspire and shape this very mammoth terminal building, whose sheer scale and size awes the onlooker. The two wings evolve as structural portals and culminate into a system of roof, shading Asia’s one of the greenest airport. With a total site area of 100 acres, the terminal buildings, with elegant 300 m twin winglike hovering roofs on both sides provide complete shade to the south facing elevation and protect the departing passengers from heat gains.

The planning of the airport is laid on the foundation that “as sustainability is sowed, sustainability will grow”. By implementing facets of sustainability in every quarter of building design and planning, the green terminals are pillars of sustainability. With such righteous intentions, the acquisitions of green ratings are reduced to a mere formality.

Terminal Planning

“Shaping Asia’s Greenest Airport”

The efficiency of the terminal can be attributed to its meticulously planned spaces. The H-shaped plan is what forms the very genesis of this sustainable terminal. A design stroke, scooping out the redundant belly of the terminal, formulated an H-shaped plan. Creating seven visible facets, transparent ingress were creating to the terminal as compared to the conventional four façade system in an ordinary terminal. Not only did it bestow the passengers with green landscape views, breaking the monotony created by security processes inside the busy airport, but also ample daylight reached every nook of the building. This planning strategy clearly exemplified that “Even Big can be sustainable”.

Think Green: Bringing lush green landscape to upper levels

Beautifully tied up with vertical landscaping, the terminal airport seamlessly blurs boundaries between inside and outside. Arriving through the majestic glass tube, instantly releases the travel fatigue as one is visually treated to the lush vertical gardens. With a layer of glazing all around and surrounding greens, the passengers are offered views to the green. The building is designed around two green courtyards termed as the central green spine. The two wings are connected by an elliptical glass tube which is positioned amidst the vertical greens giving the visitor an experience of walking among the greens. The landscape is dotted with vertical gardens and lush planting strips with interspersed reflection pools and local palm groves. Vertical gardens consist of stainless steel structure lattices providing support for hanging plants including colorful vegetation such as orchids.

The domestic and international terminals are not just engineering marvels but synergized an organic form which is a beautiful combination of architecture and engineering.

Structural Concept

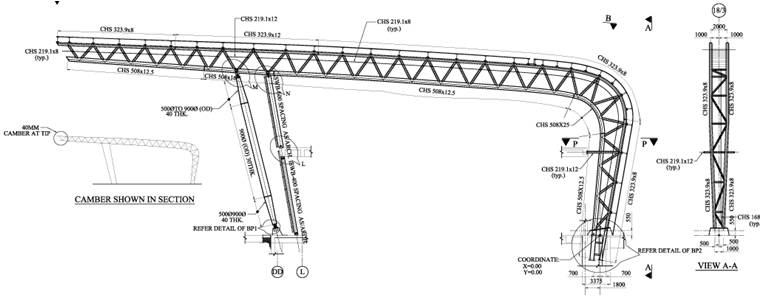

The virginity of the structural envelope at the Chennai airport beholds the otherwise hastening traveler into the airport. For both the Domestic and International Terminals, the structure essentially generates the design of the buildings. Repeating large, arching trusses offer great expanses of column-free public spaces on both the landside and airside. The triangulated truss-like structural members result in maximum efficiency from engineering, fabrication and construction considerations. By continuing the trusses at the garden facades, the large forces generated at the base of these elements are transferred directly into the foundations.

The great cantilevered curve of the front (landslide) roof structure is supported on large, paired “V” positioned full height columns. The forward slope of the columns stiffens the trusses to resist transverse wind and seismic forces. In the longitudinal direction, the paired “V” configuration of the columns works integrally with a longitudinal compression truss to create a repetitive series of stable triangulated elements that resists both longitudinal wind and seismic forces.

The space defined by the arching and curving roof has been designed so that public spaces remain column free at all terminal levels. The building’s steel structure rises with a curved roof to form a light and open, column-free terminal with expansive glass curtain walls that create a feeling of spaciousness. Skylights follow the geometry of the trusses, further opening the structural framework to allow natural light to permeate the terminal.

Design Features

Adorned in plenty of architectural elements, it is these distinct elements that give the Chennai Airport its grandeur.

Thinnest Flyover: Taking forward the V-column, to support the thinnest flyover (spanning 1.2Km), creates directly visibility from the city side. Not compromising on the visual impact of the terminal on the passengers, the flyover lets the glass terminal charm travels in style. The Thin flyover has a box frame that spans 14 meters resting on T beams, which are not only 400 mm thick but are also hollow from inside. The structural marvel not only saves more than 25% concrete but has also successfully implemented new technology of steam curing in India.

Elliptical Bridge: The Elliptical Bridge or the arrival tube connects the landside with the airside operations through the Central courtyard. The elliptical glass tube makes up for a futuristic impression, amidst the beautifully landscaped garden and thus strengthening the alliance between man and nature.

The Connecting Tube: An 800M long glass tube connects all the existing and the proposed terminals. 24 no. travellators of 1000mm width are provided for movement of passengers from one terminal to another.

Sustainability and Energy Savings

“Setting a benchmark in sustainability”

A steady combination of active and passive strategies is incorporated in terminal design and planning. Passive features such as roof insulation, fly ash in concrete, high thermal mass and use of AAC blocks minimize the heat gains in the buildings. At the same time the use of double insulated glass maximizes daylight into the terminal. Active strategies in the form of water conservation, energy efficient equipments and lighting fixtures play a vital role in energy conservation of the terminal.

An important aspect, the conservation of water has helped pushed the envelope of sustainability in a huge manner. Recycling of water by the use of STP/ETP has garnered energy savings of 50%. Coupled with latest techniques for storm water retention and ground water recharge, delivers a significant water savings of 73%.

On comparison to the GRIHA Energy Performance Index (EPI) of 450 for a similar building, the total terminal building EPI is 156.30.

It is that every small initiative taken towards energy efficiency, mounts to create the Asia, s Greenest Airport Ever.

PROJECT TECHNOLOGY

The virginity of the structural envelope at the Chennai airport beholds the otherwise hastening traveler into the airport. For both the Domestic and International Terminals, the structure essentially generates the design of the buildings. Repeating large, arching trusses offer great expanses of column-free public spaces on both the land-side and air-side. The triangulated truss-like structural members result in maximum efficiency from engineering, fabrication and construction considerations. By continuing the trusses at the garden facades, the large forces generated at the base of these elements are transferred directly into the foundations.

The great cantilevered curve of the front (landslide) roof structure is supported on large, paired “V” columns positioned full height columns. The forward slope of the columns stiffens the trusses to resist transverse wind and seismic forces. In the longitudinal direction, the paired “V” configuration of the columns works integrally with a longitudinal compression truss to create a repetitive series of stable triangulated elements that resists both longitudinal wind and seismic forces.

The space defined by the arching and curving roof has been designed so that public spaces remain column free at all terminal levels. The building’s steel structure rises with a curved roof to form a light and open, column-free terminal with expansive glass curtain walls that create a feeling of spaciousness. Skylights follow the geometry of the trusses, further opening the structural framework to allow natural light to permeate the terminal.

PROJECT SERVICES

There were many challenges associated with the project. With over 2 million sq ft of area and single spaces of 20m height, everything in MEP design was an involving process. Air-conditioning of the buildings had to be done to suit international standards. The design was completely dove-tailed with the architectural features such as the wide canopies shading the exposed glass surfaces to cut down on the heat load. The design was very peculiar since no air handling equipment space was provided in any of the usable floor space. Almost the entire air handling was located in the basement of the building. To keep the energy consumption down to a minimum, heat pipe technology was introduced in the treated fresh air units and variable flow contact was implemented both in water as well as air side.

Stainless steel displacement diffusers were designed to add to the aesthetic value of the interior design. Exhaustive network of smoke management ducts and fans were provided and the main halls in the building were also designed with smoke extraction equipment. An intensive network of equipment controls was established through Building Management System (BMS) to derive maximum energy-efficiency and a precise environment control. Energy conservation and sustainability were crucial aspects of the design. Design of water based services which plays such an important point in completing the services in any building was adopted. The design of the complete system was centralized, with the storage, treatment and distribution system located at a single place. Domestic water supply for hand wash was separated from the flushing water which had to be sourced from the STP. Sensor based taps and flushing cisterns were provided in all the toilets. The water supply distribution had been planned through hydro pneumatic pressure pumps to provide pressure even at the farthest outlet and without any overhead tank storages. Drinking water supplies and hygiene were ensured with centrifugal RO plants and use of stainless steel piping. Waste water from the buildings was designed for a disposal through a network of sewage pipes to a modern STP. A 2 MLD capacity Membrane Bio-Reactor (MBR) technology-based STP which required minimum space has been planned to churn out recycled water to be used for flushing, cooling towers and horticulture.

To light up the entire project and to power up the infrastructure, a simple yet substantial equipment base was set up. A completely new 110KV electrical intake station has been set up dedicated to the airport. Further, small electrical substations have been set up in the individual buildings to reduce power losses. Emergency situation have been designed to be taken care of by centralized UPS systems so that even a second of lighting failure and threat to critical security and IT systems is not experienced.

Lighting design has been completely integrated with the architecture, making full use of the sources of natural light which have been meticulously planned by the architects, thus resulting in huge power savings. Sensor controlled lighting for various areas have also added to the savings initiative.

The complete MEP design including HVAC, Electrical, Fire Alarm and Detection and Fire Fighting have been dove-tailed with each other so that the building behaves in unison in the event of any fire incident. Early warning systems have been installed to scan the halls for even the slightest hint of smoke. The building has been made intelligent by taking all the three key element of electronic infrastructure – monitoring and control of services, Information processing and Communications – and bringing them to their most efficient levels. The control and monitoring of all equipment has added in maximizing equipment life and minimizing down time which is so crucial for a facility such as an airport.

Passive and active green strategies

Combination of active and passive green strategies shape both the terminals. In addition to shape, size and orientation, much thought has been added to the material application of the building. Where autoclaved aerated blocks (A.A.C) and double glazed structural glazing shield the façade from the harsh solar gains, the double layer of aluminum roofing system restricts thermals roof gains. A sheet of green grass pavers helps to minimize the hard surface, by creating a permeable membrane to water absorption.

In addition, use of active strategies such as water conservation and management play a fundamental role in imparting the terminals there much adorned sustainable stature. Recycling of water by use of STP/ETP so that fresh water is only used for drinking/washing and recycled water is used in HVAC, gardening and flushing results into a 50% saving. Coupled with latest techniques for storm water retention and ground water recharge, delivers a significant water savings of 73%. Application of energy efficiency equipment and building management system (BMS) truly renders to create a smart airport of the new generation.

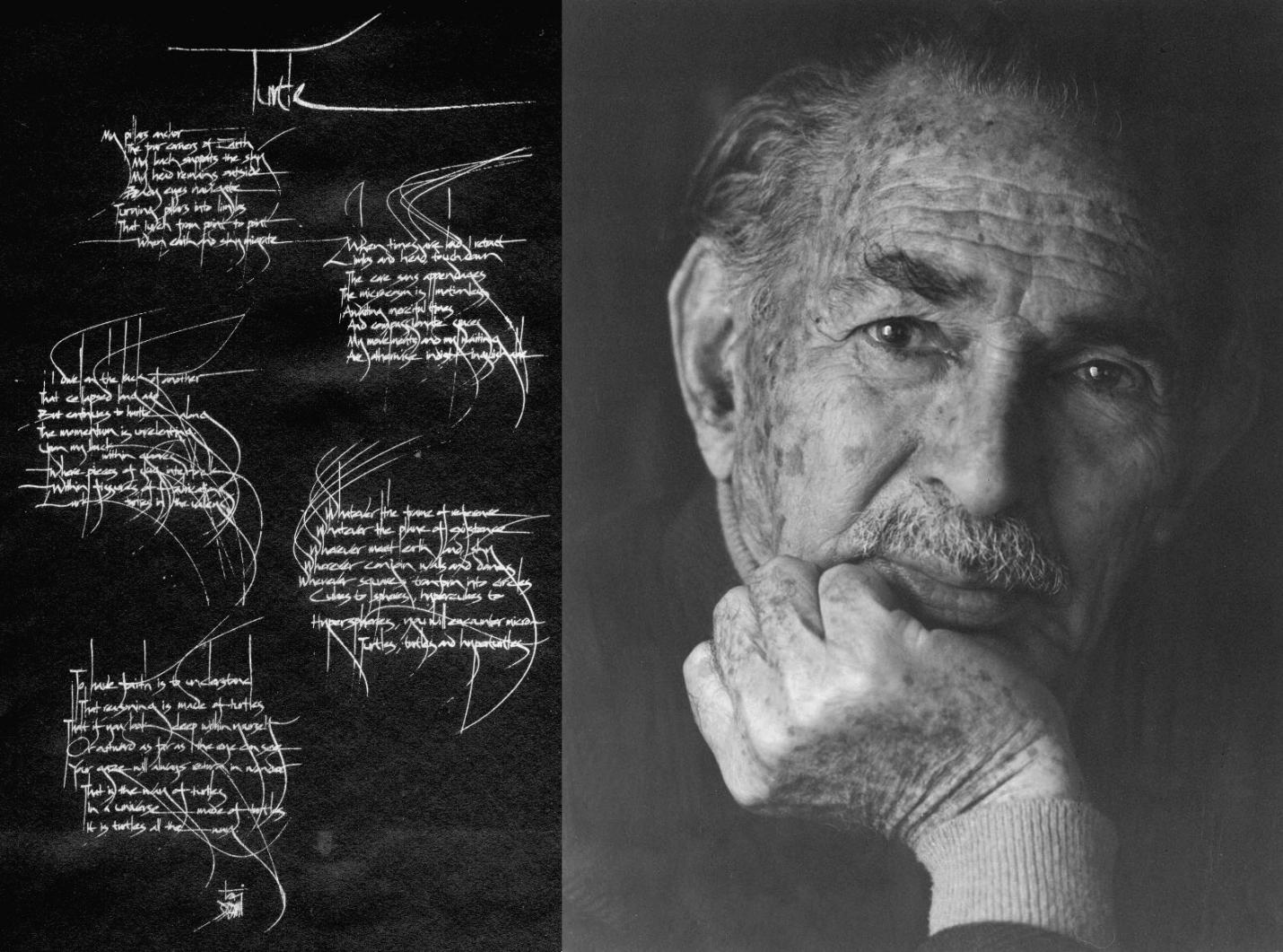

Not the one to rest on his laurels, the architect from the very inception of this dream, aspired to design a terminal with sustainability at its core. Out to challenge the general perception that airports are energy guzzlers, Prof Shah with his belief and conviction, diligently infused every space, every detail and every element of the building with inherent principles of sustainability. Not only inspiration was taken from the traditional sustainable strategies, but also many new innovations in design and construction were carved in the way. The resultant is a path breaking terminal, with unmatched parallels in sustainable design.

Images: